Sections Include:

- Overview

- Simple Calculation Methods

- Impeller Design effect on Head Pressure

- Effect of Electromagnet design on Pump Head Pressure

- Head Pressure Improvement Suggestions

By Carl Strohmeyer-PAMR 40+ years experience

Updated 11/1/21

An aspect of any water pump (not air pump), including the water pump aspect of an aquarium canister filter, a significant factor in choosing the correct pump is head pressure.

I will attempt to describe in basic and more advanced terms the important aspect of "mating" a correct water pump to your aquarium or pond application, including the addition of placing a UV Sterilizer in the line up.

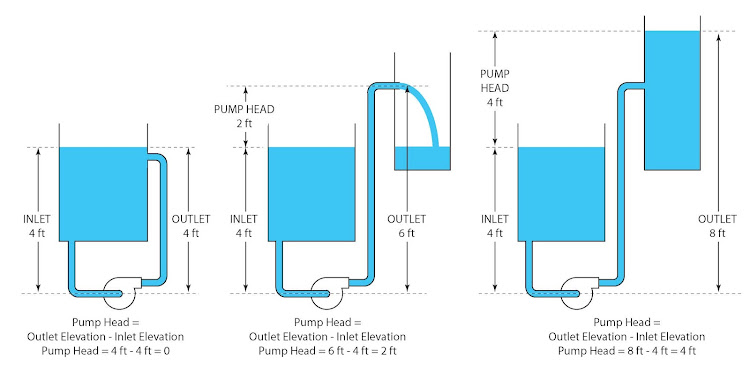

The most simple definition of head pressure is that this is the force (or resistance) placed on the "head" (OUTLET) of the pump by gravity. The weight of the water column past the point of the pump outlet and devices in-line past this point constrict or impede flow. A UV Sterilizer, pond "spitter", fountain, waterfall feature, or Fluidized Filter all can affect head pressure.

Do not confuse this with the INPUT side of a pump, any resistance or variances in flow placed on the input side of a pump can damage a pump, especially the popular Mag-drive pumps used today by most aquarium & pond owners (in applications of possible input resistance, a direct drive pump should ONLY be used)

In other words the ability to LIFT water while maintaining current (think torque in a truck that allows the "lifting" or pulling of a load up a hill). This is not simply moving water on a level plain as flow, directly out of the water pump with no pressure placed on the pumps flow.

Another way to think of this is to take a 5 gallon bucket full of water. To simply tip and pour water out of the bucket takes very little energy or "lift" (as an example of head pressure). However, if you were to climb a ladder and pour this same bucket, it would take more energy or lift to do so (again as an example of head pressure).

The majority of aquarium and pond water pumps list their maximum head pressure, so this can be used to determine the end water flow (after head pressure is applied). This may be essential for not only determining the correct pump to purchase, but the correct UV Sterilizer (if desired) to be purchased since flow rate is a MAJOR FACTOR in UVC Sterilization effectiveness.

The listed "GPH or "LPH" is almost always the flow rate directly out of the pump (head) WITHOUT ANY pressure from tubing, devices, filter media, or even water or gravity applied.

An example/analogy would be a car/truck engine: the rated horsepower is what the engine produces at the crank shaft, not the wheels after transmission, vehicle weight, etc is applied. So as a rough analogy; a 200 hp engine is going to work much better in a 2000 lb vehicle than a 10,000 vehicle. This analogy applies to a pumps rated flow rate before head pressure is applied.

"Real World" Canister Filter Flow Rates:

A pump in a sump is an open system, where as a motor/pump as part of a canister filter is a closed system by virtue of the aid of a siphon. This Siphon aid also applies if we were to use a water pump placed in the aquarium to power the canister filter, which I have often done when the motor has failed (this is less expensive than a new filter and often makes for an easier starting filter).

This siphon aid results in much lower affects of distance upon water flow rate between a canister filter and a pump in an open sump.

What is noteworthy is that despite this siphon aid, tests and 1000s of practical use applications show that there is still a drop in flow rate for a closed system canister filter due to friction, tubing size, devices such as UV Sterilizers, CO2 equipment, etc. along with some impact from head pressure.

This sometimes confusing aspect also applies when one product is more factual in publishing flow rates with what a canister filter's closed system pump will deliver in a "real world" application than another.

An example here would be a Sunsun 303B Aquarium Canister Filter which like most related filters provides only the gph (370 gph) immediately at the "head" of the pump, while the Rena Filstar XPL provides both the immediate flow rate out of the pump head (350 gph) and the ACTUAL flow rate (187 gph) out of the filter itself after hoses, filter media, etc are applied.

Based on questions, many will think the SunSun and related filter is substantially stronger, when in reality these filter are nearly equal once head pressure is applied.

Recommended Product Sources:

*Sunsun 303B Aquarium Canister Filter

*Rena Filstar XPL Premium Canister Filter

The implications here are important for mating an effective UV Sterilizer to the correct filter (if a canister filter is to be used to drive water through the UV Sterilizer). As noted previously, few canister filters rate their "true" flow rate. Another example is the Fluval FX5 with a 0 head pressure rating 925 gph, when in reality the typical head pressure flow rate is 600 gph or less after the added resistance in the filter media and tubing are applied (as well as the addition of a UV Sterilizer).

Though it's far from an exact formula, a typical pump/canister filter flow rate with an under tank placement is about 50% to 60% of the published 0 head flow rate.

This is the number you should use for mating your UV Sterilizer.

It's noteworthy that you can increase or decrease the head pressure by the placement of the pump/canister filter and other equipment run off the filter. Keeping the tubing length to a minimum can help decrease friction & head pressure as well as to not use under sized inside dimension tubing.

Impeller, intake, internal flow, and exhaust design will also play a role, as I have seen one canister filter brand barely affected by placement, whereas another is much more affected by filter placement.

Here is an actual test using the Filstar S and timing its flow to fill a container.

- Level with the aquarium - 164.53 gph

- 24" below the aquarium - 153.00 gph

- 52" below the aquarium - 142.87 gph

These results were with a filter with NO resistance in the filter (all media was removed). The tubing was not cut, shortened or lengthened (as tubing length can also change results by adding more water resistance).

For example you can have an aquarium where the stand or table it is placed on allows for the filter and other equipment to be placed alongside at the same level as the base of the aquarium. This would provide for considerably more head pressure than an installation that has the canister filter and other equipment under the stand/cabinet at say 24 inches.

Another important plumbing note is that it is important that your inflow not be impeded (which is why a pre-filter is important, especially with pond pumps), if any flow restriction is needed to control flow, this should be on the exhaust/outlet side of any pump/filter system.

Usually valves on the output/outlet side only adds more head pressure, while restricting flow on the inlet side will strain a pump/filter (this is based on decades of practical/hands on experience as well as advice from my many mentors over the years).

* An example would be a pump with the ability to pump to 10 feet; there is no difference between running this pump at zero head pressure while restricting the flow rate to that of 5 feet of head pressure versus simply running the pump uphill 5 feet to an aquarium or pond water feature!

This is why most properly designed pumps or filter often have a larger diameter intake than they do exhaust. This allows for less strain on the impeller and better head pressure.

Water Pump Designs;

Most aquarium water pumps are open impeller designs that are greatly affected by head pressure. Propeller pumps, just by their design can handle almost no head pressure and thus are only intended for under water applications with no lifting of water out or into an aquarium.

A few pumps, in particular those designed for ponds or large aquarium systems such as the Rio HF Pump series have closed designs that can handle much more head pressure and are thus better suited for lifting water through multiple devices, water features, or deep sumps.

The bottom line is, regardless of the pump design you choose, know its maximum head pressure so it can be calculated what the actual flow will be with the devices you might add in-line.

For instance, do NOT expect a 1000 gph pump with a maximum head pressure of 10 feet to pump any more than 700 gallons per hours lifting water 3 feet from a pond to a waterfall (other factors including water in-line likely will reduce this even more). It is likly that it will be closer to 600-500 gallons an hour. This also applies to aquarium applications too!

Simple Calculation Methods:

This section will provide simple and reasonably (but not 100% accurate) methods to calculate head pressure on a pump or filter.

:

This one is the most obvious; Add 1 foot of head pressure for every 1 foot of vertical tubing past the pump or filter to the discharge point in the aquarium or pond. If the pump is submersible, do not count the position in the aquarium or pond, just where the tubing leaves the top level of the water.

Do not count tubing coming from an aquarium to a canister filter as this is gravity assisted and does not add to this calculation.

This major factor of head pressure is a "one way" factor, meaning that if your pump/filter is pumping water to a UV Sterilizer 24 inches under the aquarium water level, you do NOT count the distance down, then back up as "down" is a given based on gravity/siphon. The head pressure is added on the trip back up to the tank/aquarium.

Looking at Vertical Head Pressure another way we can use this accurate formula:

1 vertical foot = 0.433 pounds per square inch (psi)

or conversely

1 psi = 2.31 vertical feet

Look at it this way; if you have a sump, and are pumping the water up, you have atmospheric pressure at the intake and you have atmospheric pressure plus the weight of the water column on the output of the pump. So before even moving anything the pump has to overcome the weight of that column, and that's where all those feet and 2.3ft/psi or 0.433 psi come from.

As an example; A pump with a rated Head Pressure of 7 feet, would have 3.03 psi (7 divided by 2.31)

Another more simplified, albeit not 100% accurate way to figure vertical head pressure loss is to find the rated maximum head pressure of a pump or filter (if published), then deduct the amount of head pressure in feet, inches, centimeters, etc.

As an example; if the maximum head pressure is 6 feet, and you are placing a pump or filter 2 feet below the aquarium or running 2 feet of water line up to a fountain or pond water feature, you can roughly deduct 1/3 off the flow. If 3 feet of water line is used for this same pump/filter, you can roughly deduct 1/2 (50%) of the flow.

There are not 100% accurate formulas that I have found for measuring horizontal head pressure, other than the very complicated Bernoulli's Equation.

Reference: Bernoulli's Equation

However both in my observations and other reading it is safe to say that horizontal head pressure equals a vertical run of .25 to .5 times its length (in an open system).

The pump outlet size is a major determining factor that you can calculate; for instance if you have a pump with an outlet designed for 1 inch tubing and you use a reducing part (often supplied with many pumps) for say 1/2 inch, you are literally going to reduce your total head pressure by half.

However if your pump is designed for only 1/2 ID tubing, using this size tubing/pipe is not going to subtract from calculation.

I also should point out that not all pumps are designed with the best outlet sizes for their design (which includes head pressure, impeller design, and more), so these calculations can be off if for instance a pump is designed with a 1 inch outlet when in reality its design is better suited for 3/4 inch outlets.

As a side note, in tests I have conducted with several pumps and 1/2 ID tubing with one foot of head added I have not been able to achieve flow rates beyond 350 gph regardless of open impeller pump sizes, wattages, stated flow rates, etc.

Many aquarium systems are designed to operate with larger diameter tubing/piping on the inlet size and smaller on the outlet.

This reduced friction and allows for better flow rate and less strain on the pump/motor.

This also applies with both closed and open systems which is why pumps such as the Rio HF pumps have a larger diameter inlet than outlet

Further Reference:

Will a Larger Pipe Size Help or Hurt?

The bottom line is this is an aspect I have often seen where clients/customers I have serviced over the years have over looked.

An example was a person who had a 3800 gph pond pump connected to 1 inch tubing, even though the pump was designed for 1.5 tubing/pipe. This reduced the flow immediately by 1/3!!

Generally speaking a Level 1 UV Sterilizer will add 1-2 feet to head pressure, but this can vary considerably by UV size and design.

As an example a small well designed 8 watt UV would add as little as a foot to head pressure, however some, such as the Coralife 9 Watt Turbo Twist can double this for a similar size UV.

A large UV such as the TMC 110 Watt PRO Pond /Aquarium UV will add as much as 4 feet of head pressure (although less if 2" ID inch pipe is used).

Product Resource:

*Level 1 UV Sterilizers

*TMC 8 Watt Vecton Premium UV Sterilizer

*TMC 110 Watt PRO Pond /Aquarium UV Sterilizer

Devices such a Fluidized Filters can add anywhere from 2 to 4 feet of head pressure (more or less).

Again design is a factor as well as the sand size (smaller requires less head pressure), but again as a generalization consider a minimum 1 foot for every 6 inches of sand fluidized plus the added elbows in the device add to head pressure as noted earlier in section #2.

Product Resource: TMC Premium 3rd Generation Aquarium Fluidized Sand Bed Filter

If this cannot be found, find a similar pump with the same input wattage and one can generally extrapolate what the maximum head pressure will be.

Then use this number for calculations of flow rate. Using an example is the best way I can explain this:

If, for example your pump/filter has a maximum head pressure of 8 feet and your device (such as a UV Sterilizer) is one foot below the aquarium or pond, you have one 90 degree bend in 3/4" ID tubing/PVC (this would add 1/2 foot head), and then the device itself would add a minimum of one foot head, this equals 2.5 feet of head pressure. Then divide 2.5 feet by 8 feet and gives you .31 or 31%.

So if the rated flow rate of said pump or filter is 500 gph without any head pressure (rated flow), then multiply by .31 or take off 31%, this equals 156 gph. Then deduct 156 from 500 and your actual flow should be 344 gph.

If all else fails in calculations or you have already purchased a pump and simply desire to know the end flow rate, this can be simply calculated quite exactly;

Simply place a container under the outlet of your pump as it empties into the aquarium or pond after passing through all devices and water feature. Then time how long it takes to fill the container in exact measurements.

As an example if a 1 gallon container fills in 10 seconds, that is 6 gallons per minute or 360 gph (this works for metric using liters too).

Admittedly this can be rather difficult for very large flow rate pond pumps that pump say 10 times the previous examples flow rate (3600 gph versus 360 gph), as this would fill 1 gallon in a second. This would required a 5 gallon bucket that might be difficult to position 100% in the water flow discharge; the end result would be 5 gallons in 5 seconds to produce 3600 gph.

Video; Calculating Aquarium Flow Turn Over

ADVERTISEMENT

Effect of Impeller design on Pump Head Pressure

The design a of a water pumps impeller has a major impact on whether it will produce higher flow rates through a higher flow rate curve.

Here are three common designs and their affect on water head pressure

(Please Click on the pictures to enlarge);

The "Propeller" pump impeller design has almost no head pressure and is not intended for any real lifting of water.

The "Propeller" pump impeller design has almost no head pressure and is not intended for any real lifting of water.

However it also is very efficient at moving reasonably high volumes of water with a very smooth rotating current and requires very low electrical wattages to do so.

These are popular in pumps such as the Premium Seio Propeller pumps for under water circulation devices, especially in reef tanks.

Another advantage of this impeller design is that it also has very low start up resistance making it the best design for wave makers that automatically turn pumps on and off to simulate waves.

Product Source: Seio 320, 530 Propeller Water Pumps for Reef Tanks, wave makers

The standard open impeller is the most common design for aquarium and light duty pond water pumps.

The standard open impeller is the most common design for aquarium and light duty pond water pumps.

While not as good for wave makers, these tend to be the most versatile design which use reasonably low electrical wattage.

Even with these impellers there is a very wide variance in design quality with some having lighter magnets, thin blades or even slight hybrid propeller designs (the Fluval Pumps have impeller designs that are not well suited for adding much head pressure).

As pure water pumps/ power heads go, the newer upgraded Rio Plus Pumps are the superior design in this class from what I have used and seen.

Product Resources:

*Rio Aquarium, Fountain Water Pumps

*Aquarium, Fountain, Pond Pumps; Light to Heavy Duty

The "closed impeller" design is generally the most heavy duty water pump impeller.

The "closed impeller" design is generally the most heavy duty water pump impeller.

This design can handle many more in line devices and its head pressure falls off much more slowly towards its maximum head pressure (where it obviously falls off to 0). In fact this is an aspect of pumps that utilize these closed impellers that is difficult to measure in the previous sections calculations (which I made many generalizations).

This design is best for deep sumps, multiple water features/devices, multiple aquarium systems, and simply larger ponds or aquariums.

A good example of a well made closed impeller pump is the Rio HF Pump

Product Resource: Rio HF Pump; Medium to Heavy Duty Water Pumps

Affect of Electromagnet design on Pump Head Pressure

This is rather straight forward, but still occasionally missed by aquarium or especially pond keepers, and that is the design of the electromagnet of most typical "Mag-Drive" pumps used for aquariums and ponds.

One way to think of this in terms of car/truck engines is horse power versus torque.

Many simple pumps (or in the case of high flow pond pumps; "cheap") have the horse power to move a lot of water, but almost no torque to lift water if there are any devices in-line or debris in the water.

The electromagnet that drives a propeller pump is generally very "simple", meaning it does not need to be a very heavy winding that uses much current, thus this design is generally quite efficient as for electrical usage. As an example a Seio 530 Pump uses only 7.5 watts yet moves 530 gph.

This is an excellent pump for what it is designed for, but it has absolutely no torque and therefore should be used for nothing more than underwater current, not running a UV Sterilizer or similar.

Product Resource: Seio 530 Pump

With most standard impeller design and especially closed (or partially closed) impeller design pumps the electromagnet is much heavier and will require more electrical current (wattage). This will obviously increase depending upon the load and flow it is designed for.

Unfortunately not all pumps marketed for applications such as ponds in particular have the heavy duty electromagnet to provide the torque to provide the "lift" necessary for head pressure.

So even if the flow is good or even the impeller design is excellent, often the electromagnet is not, so the end result is often poor head pressure or worse; a shorter life span due to an electromagnet burn out from attempting to run a large pump and impeller design (often in harsh pond conditions) with an inadequate electromagnet design.

A good example is the Via Aqua 4900 pump (although I like many Via Aqua pumps as good, albeit more economy pumps, this is one to be avoided).

Another is the entire Laguna Max-Flo pump line.

Often, but not always, a dead give away is a pump of what may seem "too low of wattage" for a high flow pump.

This may be fine a for a propeller pump, but not a pump used in sumps or ponds to lift water, especially with more debris in the water column or devices in-line.

Head Pressure Improvement Suggestions

This most basic suggestion is to adjust the level of lift if head pressure (slow water flow) is a problem.

As an example, say you are using an Internal Filter or Power Head Pump to run a UV Sterilizer (often utilizing intake and return adapters) such as the Vecton 8 Watt UV; I would recommend hanging the UV Sterilizer just below the rim of the aquarium with minimal tubing between the UV Sterilizer and the intake and return connections.

Such a short drop will reduce head pressure considerably versus placing the UV Sterilizer at the base of the aquarium or even lower such as at the base of an aquarium cabinet (which may be too much head pressure for many small Internal Filters and Power Head Pumps).

Product Resources:

*Via Aqua or SunSun Internal Aquarium Power Filters

*Power Head Pump; Efficient JP-023

The above suggestions work for many similar applications, and that is moving any device closer to the aquarium (or pond) thus reducing vertical lift.

Horizontal lift is also and issue, but not nearly as much so as vertical lift; that said reducing any unnecessary horizontal tubing/piping can improve head pressure as well.

Having direct flow, even with canister filters using bulkheads can also lower head pressure from my experience

This video provides information as to bulkhead use based on professional experience:

Aquarium Bulkhead Tips and Tricks

References, Additional Reading:

*Pipe Pressure Loss Calculator

This is excellent reading for those with a more technical engineering aptitude.

````````````````````````

For other articles to help readers make well informed decisions about their aquariums or ponds, please consider reading these:

*Aquarium Lighting; The most in depth & researched aquarium lighting article anywhere on the internet.

*UV Sterilization; Sterilizer Information

As with the Aquarium Lighting, this UV Sterilization article is a must read for aquarium or pond keepers.

*Pond Care Information;

Basic but complete information about pond care with links/resources to more in depth pond care help/information.

Other Recommended Reference & Product Sites

Sponge Filtration; Complete Aqurium Sponge Filter Use Information

Premium Aquarium Sponge Filters; from AAP/ATI

Aquarium & Pond Plumbing Parts

Difficult to find or unique parts found nowhere else!

Including: T Water Diverters, Hose Barb Adapters, Couplings, & Reducers, Ball Valves, Swing Check Valves, Return Adapters, Intake Adapters

Economy Submersible Aquarium, Fountain Pumps; SunSun JP-033

A better, UPDATED version of the Via Aqua 302 with SUPERIOR Performance, unlike other pumps sold elsewhere as a replacement

AAP/SunSun HJ-1542 Aquarium Pump; replaces Via Aqua 1300

This pump replaces the Via Aqua 1300 and other copies such as by AquaTop as the Premier Power Head Pump for Aquariums, Ponds, Fountains, Wet/Dry Filters. This pump is submersible with Mag drive & ceramic shaft

JTP-12000 High Output/Efficiency Pond Pump, 3170 GPH (12000 LPH)

Unique VERY efficient design; uses variable frequency technology for low power consumption yet large flow rate & high head pressure!

Uses only 100 watts for 3170 gph output

Hanna Instruments Aquarium Testers & Meters; For Freshwater and Saltwater

Hanna instruments is a global manufacturer of analytical instrumentation.

Hanna offers multi-parameter bench top portable meters and testers..

AAP Premium FSB Filters

Premium, second to NONE Aquarium Bio Filters, that with optional Oolitic Sand can also maintain essential aquarium calcium levels, alkalinity, & electrolytes that are important to ALL Marine life, Goldfish, African Cichlids, Livebearers & more

*Aquarium Silicone Sealant; USDA 100% Fish Safe

100% Fish Safe, USDA & Agricultre Canada approved.

The same CANNOT be said for Hardware Store brands!!

For a friendly, Knowledgeable, aquarium forum with in a family atmosphere:

Aquarium Forum; Everything Aquatic

ADVERTISEMENT